Ring oss

+86-19858305627

Send oss en e-post

sales@maple-machinery.com

Marine stålstøpedeler Produsenter

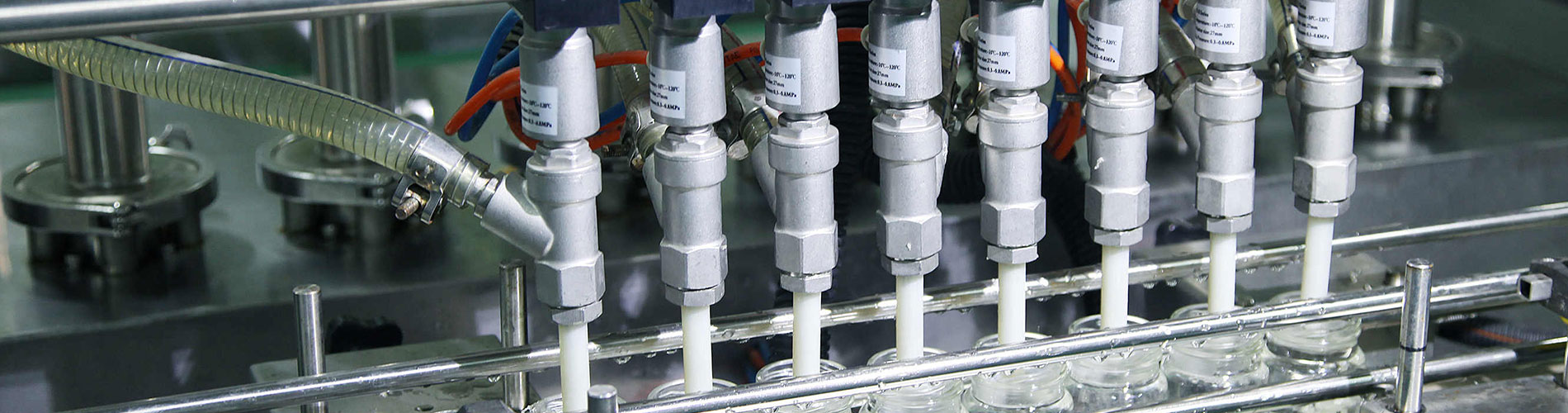

Fabrikken vår tilbyr sandstøping, lukket formsmiing, åpen formsmiing, etc. Ekstremt design, kvalitetsråvarer, høy ytelse og konkurransedyktig pris er det enhver kunde ønsker, og det er også det vi kan tilby deg. Vi tar høy kvalitet, rimelig pris og perfekt service.

Varme produkter

Landbruksmaskiner Stål Tapt voksstøpedeler

Maple machinery er en fremtredende leverandør. I tillegg til deres rolle som kommersielle leverandører, krever de relativt høye ytelsesmålene som kreves av disse applikasjonene tilsvarende strengere spesifikasjoner. Landbruksmaskiner Steel Lost Wax Casting Parts er et av våre beste produkter. Et stort antall eksport hvert år er et bevis på vår styrke.Olje- og gassindustrien Stålsmideler

I flere tiår har Maple-maskineri vært en stor leverandør til olje- og gassindustrien, og levert høy kvalitet og konkurransedyktige priser. På grunn av de tøffe miljøforholdene i olje- og gassindustrien, undervanns-, overflate- og hydraulisk fraktureringsindustrien, sikrer Maple materialer av høyeste kvalitet og smiingsnøyaktighet gjennom smiressurser, evne og erfaring, og produserer de beste stålsmiingsdelene i olje- og gassindustrien i korteste leveringstid.Marine Steel Lost Wax Casting Parts

Maple machinerys infrastruktur er videre delt inn i underavdelinger, slik som produksjon, kvalitetstesting, salg og markedsføring, etc., for å sikre jevne forretningsprosesser. Våre produksjonsenheter er utstyrt med det nyeste utstyret og moderne teknologi for å gjennomføre en smidig produksjonsprosess. De dyktige og erfarne medarbeiderne i teamet vårt er kjent med utstyret og maskineriet som er installert, noe som gjør oss i stand til å produsere de aller beste kvalitetene til støpedeler for tapt voks av stål.Landbruksmaskiner Støpedeler i rustfritt stål

We have rich experience in the field of steel, steel, aluminum, special alloy and other agricultural machinery. All Agricultural Machinery Stainless Steel Casting Parts are made by different processes, including sand casting, investment casting, centrifugal casting, die casting, forging, machining, etc. We have been serving international industrial markets for more than 15 years. Our primary goal is to retain the loyalty of existing customers and win new business through exemplary customer service, low cost, high quality, fast shipping, complete order fulfillment and custom processing. 产品内容 Agricultural Machinery Stainless Steel Casting Parts Product Introduction Maple machinery's services include heat treatment, machining and surface treatment. Heat treatment involves heating and cooling a metal to change the physical and mechanical properties of Agricultural Machinery Stainless Steel Casting Parts. Heat treatment controls properties such as hardness, strength, toughness, ductility, and elasticity. We also offer a full range of machining services. With our surface treatment service, we can treat your products to improve corrosion resistance, wear resistance and appearance. 2. Product Parameter (Specification) Item Agricultural Machinery Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Agricultural Machinery Maple machinery is one of the trusted and reliable manufacturers and suppliers of Stainless Steel Casting Parts, Vick serves the global needs of Agricultural Machinery Stainless Steel Casting Parts and ensures high quality products and on-time delivery in every transaction. In our foundry, we mainly process carbon steel and alloy steel materials. We inherited the casting process from our great-grandfather, and have a skilled labor force and professional technical experts to meet different needs. 4.Supporting Service for Agricultural Machinery As mentioned above, in order to work in adverse conditions, the performance of the Agricultural Machinery Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Agricultural Machinery Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Agricultural Machinery We have manufactured a wide range of Agricultural Machinery Stainless Steel Casting Parts. The following are typical products: Brackets, Rototiller tines, Tillage Points, Seed Drills, Chain Sprocket Locust Harrows, Levers, Plough, Pivots, Covers, Clevises, Handles and Latches, Suitcase Weights, Pumps & Valves, and Hardware.. 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.Olje- og gassindustrien Gråjernstøpedeler

Fra Gray Iron Casting-ingeniører, teknikere, formenn, modellbyggmekanikere og modellbyggere i produksjon til industrielle mekaniske og elektroniske teknikere eller industrielle ledelsesassistenter i vedlikehold, de gjør sitt beste hver dag for å glede våre olje- og gassindustrikunder med støpegods av høy kvalitet. Fra rådgivning og ordrebehandling, til arbeidsforberedelse og produksjon av olje- og gassindustriens gråjernsstøpedeler, til dyp bearbeiding og transport, som et team, forfølger vi et felles mål: å produsere komplekse og høykvalitets gråjernsstøpedelerGjenvinningsindustri Gråjernstøpedeler

Lønnmaskineri Sandstøpeprosessen produserer gjenvinningsindustri Gråjernstøpedeler. Sandformer er laget av tre eller metallmønstre. Den finkornede sanden ble blandet med harpiksbindemidlet i en hurtigblander og helt over i mønstrede bokser. Etter noen minutter herdet sand-limblandingen og formen ble fjernet fra mønsteret. Den samme prosessen brukes for kjernene som brukes til å lage den indre strukturen til støpegodset.

Send forespørsel

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy