Ring oss

+86-19858305627

Send oss en e-post

sales@maple-machinery.com

Presisjonsstøpegods og maskinbearbeidede deler for olje- og gassindustrien Produsenter

Fabrikken vår tilbyr sandstøping, lukket formsmiing, åpen formsmiing, etc. Ekstremt design, kvalitetsråvarer, høy ytelse og konkurransedyktig pris er det enhver kunde ønsker, og det er også det vi kan tilby deg. Vi tar høy kvalitet, rimelig pris og perfekt service.

Varme produkter

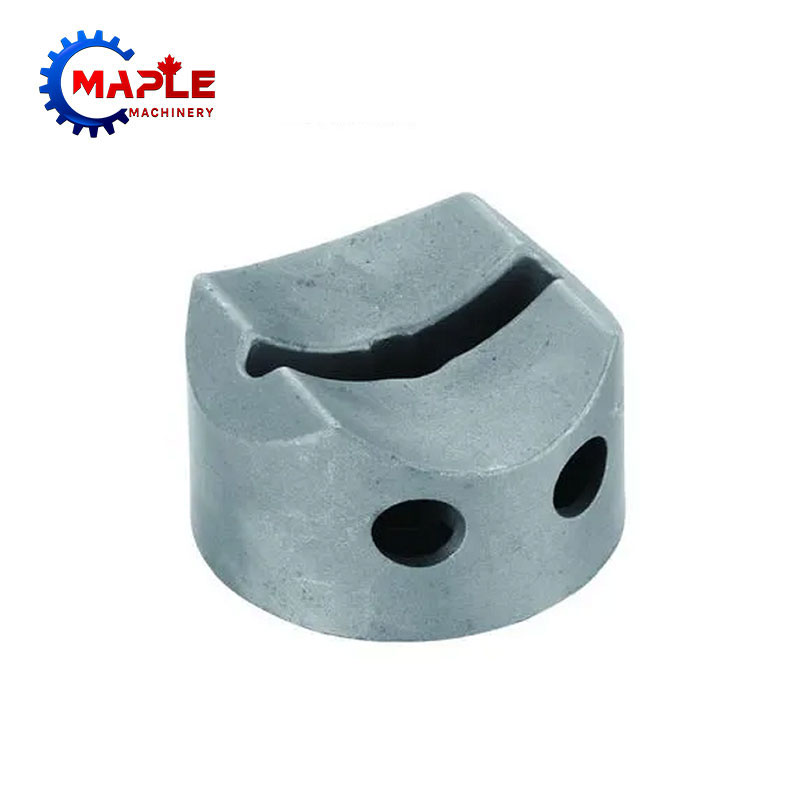

Gruveindustrien Rustfritt stål smiing deler

Maple-maskineri produserer rustfritt stålsmiing. Vi utvikler og produserer gruveindustriens rustfrie smideler i henhold til tegninger eller prøver levert av kunder. Først av alt gjør vi en tilsvarende sjekk etter hver prosess. For sluttproduktet vil vi gjennomføre 100 % full inspeksjon i henhold til kundens krav og internasjonale standarder. Med utmerket kvalitet, service av høy kvalitet og konkurransedyktig pris stoler kunder på gruveindustrien.Gruveindustri Gråjernstøpedeler

Maple machinery er en produsent av gråjernstøpedeler i gruveindustrien for gruveindustrien. Vi leverer produkter, spesialiserte metallurgiske produkter og produksjonsutstyr, og gir nødvendig konsulentstøtte. Med over 15 års erfaring i disse bransjene kan vi hjelpe med å finne den beste teknologien og utstyret for gråjernsstøping og overflatebehandlingsprosesser.Resirkuleringsindustrien Rustfritt stål smiing deler

I jakten på en mer bærekraftig verden har resirkuleringsindustrien rustfrie smideler vist seg å være en verdifull alliert for arkitekter, ingeniører og entreprenører, med flere fordeler ikke bare for prosjekter, men for samfunnet som helhet. Fordelene ved å bruke resirkulerte industrielle rustfrie smideler inkluderer reduserte prosjektkostnader og økt estetikk, pålitelighet og forutsigbarhet. Fra et bærekraftssynspunkt kan det å kombinere rustfritt stål med avanserte materialteknologier nå nye høyder.Marine rustfritt stål støpedeler

Maple machinery is a professional manufacturer located in Ningbo, China. More than 15 years of experience in the steel industry. Our products mainly include Marine Stainless Steel Casting Parts. Our products have been exported to many countries in Europe and America. We have a wealth of foundry experience, but also a number of stable Marine industry customers.产品内容 Product Introduction Maple machinery offers a wide range of custom Marine Stainless Steel Casting Parts. Stainless steel is resistant to corrosion and heat, has aesthetic appeal and low life cycle cost, is fully recyclable and has a good strength-to-weight ratio. We offer austenite, ferrite, martensite and biphase grades: we have hot or cold rolled and various surface treatments such as bright annealing. You can count on our experience. 2. Product Parameter (Specification) Item Marine Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Marine Maple machinery has been the most demanding supplier of Marine Stainless Steel Casting Parts for more than 15 years. Our reputation has earned us partners and valued customers who follow the most stringent requirements in terms of microstructure integrity, dimensional tolerances and quality control. Our products meet customers' requirements and standards. 4.Supporting Service for Marine As mentioned above, in order to work in adverse conditions, the performance of the Marine Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Marine Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Marine We have manufactured a wide range of Marine Stainless Steel Casting Parts. The following are typical products: Ground engaging tools: drill bits, carbide tipped tool, forged bucket tooth, auger.... 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.Matprosessmaskin duktilt jernstøpedeler

Siden oppstarten har vi vært forpliktet til området produktivitetskapasitet, for å møte den økende etterspørselen fra markedet, forbedrer vi hele tiden vår matprosessmaskin duktile jernstøpedeler og kvalitet. Produksjon av alle produkter fra maskindeler til mellomstore deler for å forbedre sine egne evner. Møt kundenes behov.Gruveindustrien Stål lukket die smiing deler

Vårt langsiktige samarbeid med globale OEM-er har gitt oss kunnskap utover dine behov. Enten varmebehandling, testing, grovbearbeiding eller ferdigbearbeiding, kan vi levere gruveindustrien Stål lukkede smideler klare for montering. Vi er avhengige av vårt mest avanserte teknologi og profesjonelle ingeniørteam dedikert til kvalitet og ytelse for å hjelpe teamet ditt kontinuerlig med å forbedre delens design. Fra avansert støping til støpekonvertering er vi ikke et vanlig smiverksted.

Send forespørsel

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy