Produkter

- View as

Ventil Stål lukkede smideler

Vi tilbyr høykvalitets ventilstål lukkede smideler, samt fleksibilitet og ansvarlighet for å møte de høye kravene til ventilindustrien så vel som utover. Enten det er ventildeler eller andre formsmiingsdeler, vi produserer dem i Maple-maskineri. Nyt den samme kvaliteten og kundefokuserte tilnærmingen. La oss fullt ut utvikle og produsere stål lukkede smidninger

Les merSend forespørselHeavy Industry Steel Closed Die Smiing Parts

Maple-maskineri spesialiserer seg på lukket formsmiing, og produserer høykvalitets tungindustristål lukkede formsmiingsdeler. Vår virksomhet er global markedsføring. I dag har selskapet etablert langsiktige samarbeidsrelasjoner med mange kjente kunder i inn- og utland. Kulturen til Maple-maskineri er å skape verdi for selvutnyttelse. Dens største fordeler er kundene. Som et resultat har Maple-maskineri vært og vil fortsette å være en pålitelig og dedikert partner for våre kunder.

Les merSend forespørselMarine stål smideler

Som en hovedtype metallsmiing er stålsmiing en teknologi for stålforming som bruker lokal kompresjonskraft. Smiing har gjennomgått betydelige endringer, noe som har ført til mer effektive, raskere og lengre varige prosesser. I dag utføres marine stålsmideler vanligvis med elektriske, hydrauliske eller trykkluftdrevne smipresser eller hammerverktøy. Varmsmiing innebærer oppvarming av arbeidsstykket til ca. 75 % av smeltetemperaturen.

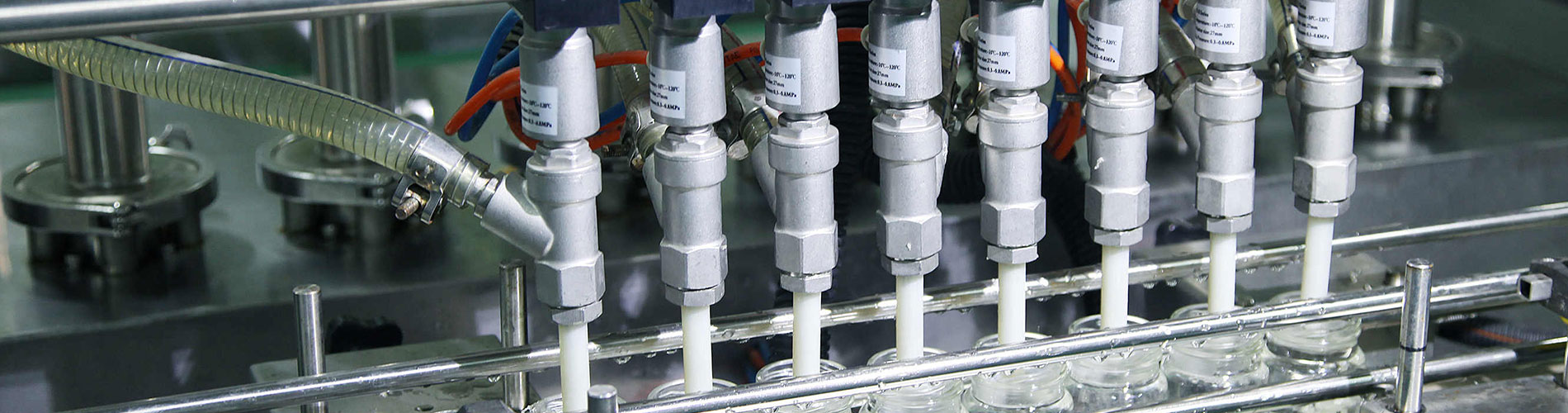

Les merSend forespørselMatprosessmaskin Stålsmiingsdeler

Maple machinery investerer kontinuerlig i utviklingen av våre mennesker, prosesser og maskiner for å nå våre utviklingsmål. Investeringer og innovasjon har sikret standarden for matprosessmaskinstålssmiingsdeler. På grunn av den kontinuerlige interne utviklingen og vår streben etter perfeksjon, har vi blitt anerkjent av kundene.

Les merSend forespørselVentil Stål smideler

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.

Les merSend forespørselTungindustri stål smiing deler

Maple machinery er en raskt voksende leverandør av smiprodukter i Kina, fokusert på å møte utfordringene til dagens smiprodukter. Det har vært en høyprester siden oppstarten og er en av de ledende smileverandørene av ulike stålkvaliteter til tungindustrien. Maple-maskineri er anerkjent av anerkjente kunder og testbyråer for sine høykvalitets stålsmideler for tung industri. Vårt firma har alltid fokusert på den mest avanserte teknologien for å gi bedre smiprodukter år etter år.

Les merSend forespørsel