Ring oss

+86-19858305627

Send oss en e-post

sales@maple-machinery.com

Støpegods av duktilt jern Produsenter

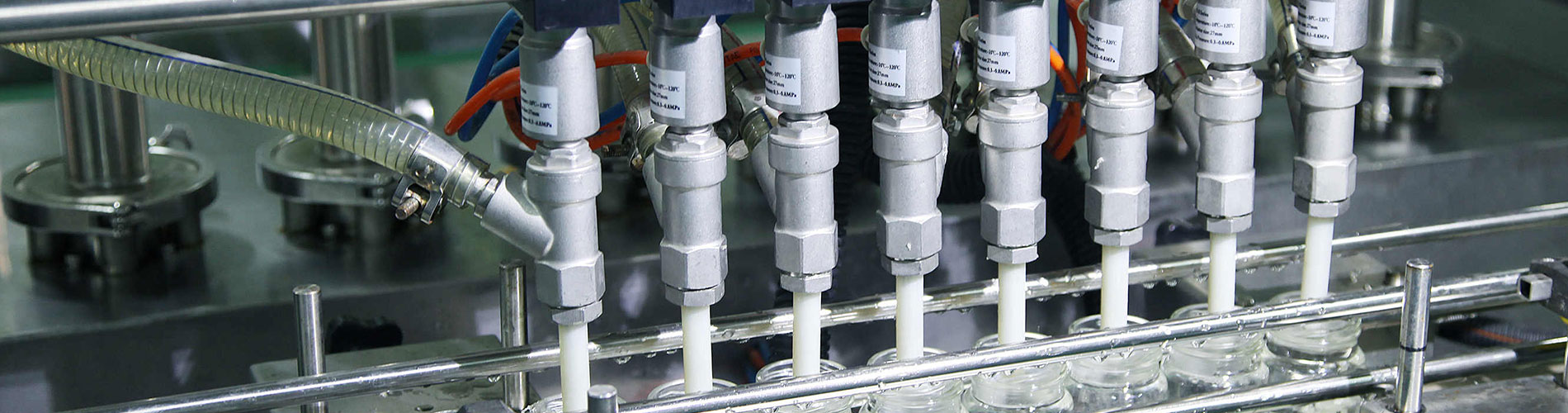

Fabrikken vår tilbyr sandstøping, lukket formsmiing, åpen formsmiing, etc. Ekstremt design, kvalitetsråvarer, høy ytelse og konkurransedyktig pris er det enhver kunde ønsker, og det er også det vi kan tilby deg. Vi tar høy kvalitet, rimelig pris og perfekt service.

Varme produkter

Resirkuleringsindustrien Stål presisjonsstøpedeler

Maple-maskineri har alltid levert den høyeste kvaliteten skreddersydde Resirkuleringsindustri Stål Presisjonsstøpedeler-tjeneste. Vi gir våre kunder det høyeste nivået av kvalitetsdeler og tjenester. Vår tjeneste for gjenvinningsindustri for presisjonsstøping av stål er designet for å møte de nøyaktige behovene til våre kunder, og teamet vårt er forpliktet til å gi verdi gjennom presisjonsteknikk og innovative verktøyfunksjoner.Marine grå jernstøpedeler

For å nå våre utviklingsmål investerer Maple machinery kontinuerlig i utviklingen av våre mennesker, prosesser og maskiner. Investering og innovasjon sikrer en perfekt match mellom det fascinerende håndverket til Marine Grey Iron Casting Parts og behovene til dagens og morgendagens verden. Som et resultat av konstant intern utvikling og vår streben etter perfeksjon, er vi anerkjent som en av de beste grunnleggerne i verden. Vi er en klar leder innen teknologien som brukes i støperier og maskinverksteder, og vi er veldig stolte over denne prestasjonen.Landbruksmaskiner Stålstøpedeler

Maple Machinery gikk inn i landbruksindustrien for flere år tilbake, og har i dag et bredt og vellykket marked i Europa og Nord-Amerika. Vi har en voksende liste over lojale kunder som er avhengige av høykvalitets landbruksmaskiner stålstøpedeler for sin landbruksindustri. Vi kan vinne kundenes tillit kun på grunn av våre profesjonelle tjenester og høykvalitetsprodukter basert på avansert teknologi.Marine stål smideler

Som en hovedtype metallsmiing er stålsmiing en teknologi for stålforming som bruker lokal kompresjonskraft. Smiing har gjennomgått betydelige endringer, noe som har ført til mer effektive, raskere og lengre varige prosesser. I dag utføres marine stålsmideler vanligvis med elektriske, hydrauliske eller trykkluftdrevne smipresser eller hammerverktøy. Varmsmiing innebærer oppvarming av arbeidsstykket til ca. 75 % av smeltetemperaturen.Sivilingeniør Stål Sandstøpedeler

Maple machinery er et selskap som spesialiserer seg på produksjon av små og mellomstore støpegods i støpejern og stål. Butikken produserer en rekke produkter for Civil Engineering Steel Sand Casting Parts. Alle produkter er laboratoriekontroll, og utstedt produktkvalitetssertifikat.Anleggsmaskiner Gråjernstøpedeler

Gråjernstøpedeler er vanlige metallstøpegods i metallbearbeidingsaktiviteter. Prosessen involverer smelting av støpejernsmaterialet og fylling av den smeltede væsken i en form for å danne en støpegods. Støpejern har en veldig lang tradisjon tilbake til 1200 f.Kr., og i dag bidrar støpejernsstøpegods i stor grad til en rekke livsapplikasjoner Byggemaskiner. Vi kan se at det er mange produkter fra støpejernsstøping og anleggsmaskiner Gråjernstøpedeler.

Send forespørsel

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy